1. Tiandi lid box: first take a look at the product to see if there are any problems such as printing, bronzing, bumps, scratches, glue, wrinkles, etc. on the appearance, and then see if there are wrinkles and leaks in the material, wrapping, positioning , Dirty spots, empty, glue, glue, etc., whether the four corners of the molding are smooth, high and low angle.

2. Mid-seam lid box: In addition to the above problems, pay attention to the tightness of the middle layer, such as seamless gaps, glue, high and low angles, damage, etc., and see if there are obvious gaps after closing the lid. The size of the four sides when covering is not the same, whether it is uniform enough.

3. Cylinder box: In addition to the surface problems, the cylinder is not round enough, the bottom plate has no gaps, there is no glue around the inner layer, and the surrounding edge is not smooth enough.

4. Clamshell box: the appearance is the same as above, pay attention to the direction of the external connection label, whether the seats left, right, up, down, left, and right of the external connection label affect the appearance. After opening, first see whether there is any obvious deviation after opening. Are the four sides of the inner cover label and the connecting label attached well? Are there any leaky edges or gray boards on the four sides of the inner lining? Is the middle layer high or low angle glue installed? Are there any damages to the middle layer? Will the inner tray be too loose or too tight?

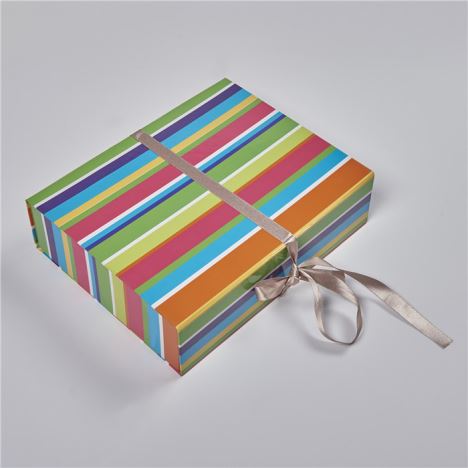

5. Folding box: After molding, pay attention to the box lying flat on the table, whether there is a 90-degree angle on all four sides, whether there is any obvious gap in the lid, whether the size of the left and right sides is the same, and whether the internal and external imposition positions are folded. Wrinkled, whether the four-sided double-sided adhesive tape is attached, pay attention to the front and back sides of the ribbon, the length of the ribbon, whether it is affixed according to the customer's required seat size, the tail of the ribbon cannot be fluffed, the lining of the ribbon can not be pulled, the four sides Do not spill or penetrate the glue.

6. Drawer box: In addition to the above box type problems, pay attention to the size of the drawer to ensure that the tightness is moderate, not too tight or too loose.

Related Industry Knowledge

- How do custom gift box manufacturers survive th...

- The Influence of Printing Color Difference on t...

- What are the specific requirements for custom g...

- What kind of customized gift boxes need to be c...

- How to choose various materials when customizin...

- What printing methods are generally used for ma...

- Why are hardcover custom gift boxes so much mor...

- Answering some questions about making customize...

- Where is the price difference of gift boxes pro...

- Points to be aware of when making hardcover cus...

- How to solve the problem of non-sticky glue for...

- Senior personnel of gift box manufacturers tell...

- What is the evolution of custom gift box making?

- What is the difference between customized gift ...

- How can custom gift box manufacturers increase ...

- Why are the prices of customized gift boxes of ...